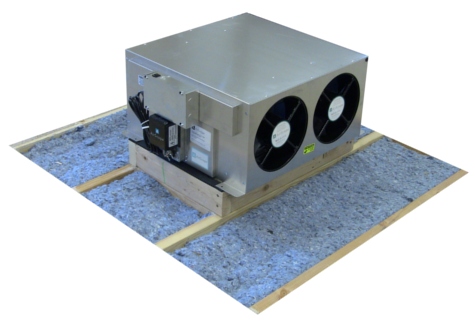

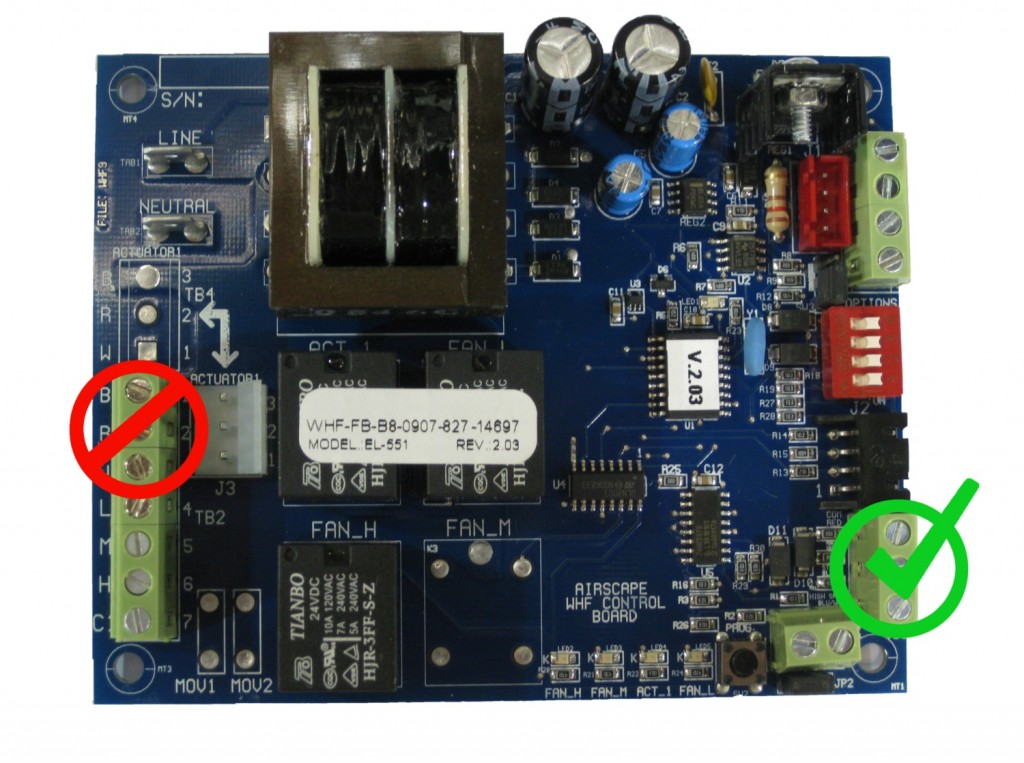

This is a brief reminder of the proper location for wiring the wall switch to your AirScape control board. We have noticed that sometimes people, even licensed electricians, wire the wall switch to the auxiliary actuator terminal (red crossed out circle). Wiring at this incorrect location will blow the 3 amp circuit breaker on your unit and possibly damage your control board. Regardless of your experience level we recommend looking at the wiring diagram in the instruction manual before wiring the wall switch. The correct wiring location is indicated by the green circle with check mark.

This is a brief reminder of the proper location for wiring the wall switch to your AirScape control board. We have noticed that sometimes people, even licensed electricians, wire the wall switch to the auxiliary actuator terminal (red crossed out circle). Wiring at this incorrect location will blow the 3 amp circuit breaker on your unit and possibly damage your control board. Regardless of your experience level we recommend looking at the wiring diagram in the instruction manual before wiring the wall switch. The correct wiring location is indicated by the green circle with check mark.

Related Posts: HOW TO WIRE THE WALL SWITCH