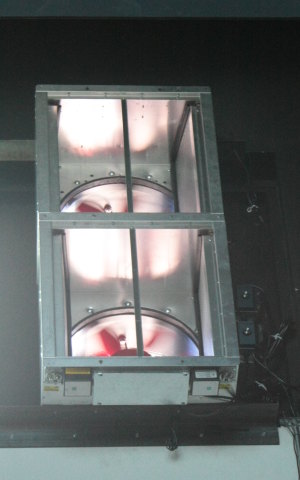

So, here is the idea proposed by one of our local green minded restauranteurs. Exhaust hoods in restaurants run almost continuously, propelling a great deal of warm air outside. The particular idea was to use this stream of warm air to pre-heat incoming water. Restaurants use a lot of hot water. Seems like a good idea… continuous exhaust of hot air, and an almost continuous need for hot water.

So, here is the idea proposed by one of our local green minded restauranteurs. Exhaust hoods in restaurants run almost continuously, propelling a great deal of warm air outside. The particular idea was to use this stream of warm air to pre-heat incoming water. Restaurants use a lot of hot water. Seems like a good idea… continuous exhaust of hot air, and an almost continuous need for hot water.

So how would you do this. A device that transfers heat from one medium (typically a fluid like air or water) to another, without contaminating or mixing the fluids is what an engineer would call for. The generic term is a heat exchanger. A radiator is an example of a liquid to air heat exchanger. A serpentine row of copper water pipes would work as a basic heat exchanger.

Now the engineering fine print. If you put this heat exchanger in the exhaust air, the exhaust fan will have to run harder to overcome the additional resistance to airflow (there is now an obstruction in the airstream). In addition, the heat exchanger will require cleaning, because restaurants are very definitely not grease free.

No piece of equipment lasts forever, so the cost to maintain or replace the heat exchanger must be taken into account. Ah, but you say saving energy is more important than money, which is a mere human construct. Perhaps, but since money is the indirect measure of human effort, we should apply some economic measurements to our proposed project. In short, we would measure the financial return on our heat exchanger investment by summing up purchase costs, maintenance costs, and on the plus side energy savings.

So, we now at least have a concept of how to determine whether this idea makes sense. It may in fact, be a great idea.

As usual,in all human endeavours, it gets more complicated. Most restaurants do not have an excess of capital, they rent their building, and perhaps most importantly, can not reasonably plan on being in business for 10+ years that it may take to recover such an energy investment.

So, here is the idea proposed by one of our local green minded restauranteurs. Exhaust hoods in restaurants run almost continuously, propelling a great deal of warm air outside. The particular idea was to use this stream of warm air to pre-heat incoming water. Restaurants use a lot of hot water. Seems like a good idea… continuous exhaust of hot air, and an almost continuous need for hot water.

So, here is the idea proposed by one of our local green minded restauranteurs. Exhaust hoods in restaurants run almost continuously, propelling a great deal of warm air outside. The particular idea was to use this stream of warm air to pre-heat incoming water. Restaurants use a lot of hot water. Seems like a good idea… continuous exhaust of hot air, and an almost continuous need for hot water. OK, first the boring defintion. A CFM stands for cubic foot per minute. This term is used as a measurement of airflow rate for ventilation systems. The cubic foot refers to a (mythical) cube of air 1 foot x 1 foot x 1 foot. CFM becomes a flow rate since we measure how many cubic feet are flowing by per minute.

OK, first the boring defintion. A CFM stands for cubic foot per minute. This term is used as a measurement of airflow rate for ventilation systems. The cubic foot refers to a (mythical) cube of air 1 foot x 1 foot x 1 foot. CFM becomes a flow rate since we measure how many cubic feet are flowing by per minute.