We had a booth at the 2009 West Coast Green show. Great venue.

Great weather. And we had a lot of fun talking to customers.

The show was held at Fort Mason, which was really at one time an Army Fort.

The show was held at Fort Mason, which was really at one time an Army Fort.

Most everything we build is designed for the worst case scenario, be it power output, strength, whatever. The only problem with this is that 90% of the time we are running a lower speed. Let me give you some examples.

Your car engine has enough power to accelerate a fully loaded vehicle uphill, in the summer heat, with a headwind, and a tailgater behind you. Great, but most of the time your car is taking one person down the freeway at a reasonable speed. Unfortunately, it’s very hard to design that motor to perform efficiently at high output power and low output power. The older ones among us remember some valiant attempts to achieve this goal, like turning off engine cyclinders. The hybrid guys just simply turn the gasoline engine off when not needed.

Of course, in the world of whole house fans, we use electric motors to power our fans. Typical AC (alternating current) fractional horsepower motors also suffer from the same problem. We specify and purchase them based on full load performance, but the part load (or low speed) efficiencies are not good at all. This is because a lot of electrical energy ends up being turned into heat while powering the internal electromagnets.

The reason we care about this, is because the ideal whole house fan will run at full load early in the evening to quickly cool the air in the house. At this point, we care more about getting comfortable than cooling the structure – so big CFM is the answer. However as the evening progresses, it’s not necessary for comfort to exhaust as much air. Also, the house probably will not cool down any faster just because we blow more air. An example of this is cooling hard boiled eggs under running cold water. If you turn up the tap all the way, do the eggs cool down faster ?

The solution is to use an electronically commutated motor (ECM). This type of motor is basically a permanent magnet motor with a small computer on top (was that technical enough?). The bottom line is good efficiency at full speed, and extraordinary efficiency at part load. Take a look at our new 2.5eWHF as an example.

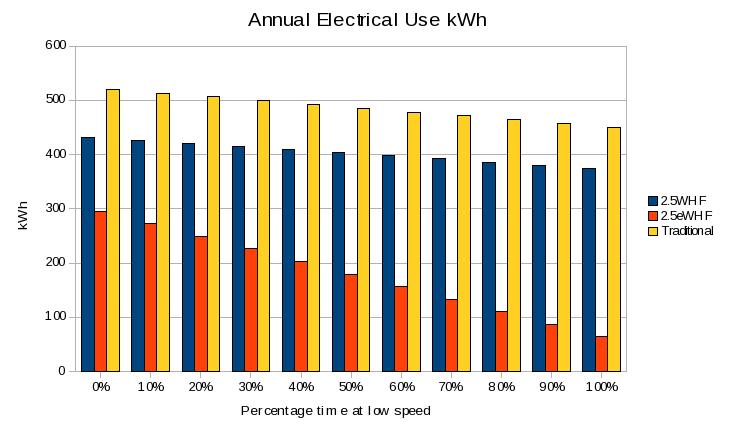

The chart at the top of the page shows the annual electrical consumption of several different WHF’s. As you can see, the more that you run in low speed, the better the ECM looks.

The concept of sustainable living, or sustainability has wide appeal. It’s hard to argue with the idea that if you think of natural resources and energy as a bank account, we should not be overdrawn.

If you do it right, and it’s a tall order, you could model the “real” costs of resource extraction. Our simplistic economic models increase the Gross Domestic Product when a tree is cut down, or oil is burnt. Basic accounting practices would at least require us to decrease the amount in our natural resource account.

Let’s table that thought. Onto the rant du jour. Our local food co-op has the following announcement:

——————————local Co-op announcement——————————————–

—————————————–\\——————————————————————

Isn’t that great? Well, of course not! Otherwise this would not be a rant.

How do you make your own salt? Evaporate the water. Great. With what energy? Electricity as it turns out.

Let’s do some calculations …

| Percent salt in seawater (by mass) | 3.50% |

|

| Energy to evaporate 1 kg water | 2,257,000 | joules |

| Efficiency of Evaporation* | 60.00% |

|

| Energy to recover 1 kg salt=> | 107,476,190 | joules |

| Convert to=> | 29.85 | kWh |

| pounds of CO2 per kWh | 1.35 | source: DOE |

| pounds of CO2 produced per 1 kg salt=> | 40.3 |

|

| * Engineering Estimate |

|

|

Bottom line. You made your own salt. If you had purchased standard packaged salt, it would most likely have been harvested using solar energy, and energy efficient vacuum evaporation process (see http://www.cargill.com/static/sb/tour.htm).

Perhaps this adventure falls into the self-contained, but not sustainable category.

We’re getting ourselves ready to build some software to help predict whole house fan energy savings. In the meantime, I put together this spreadsheet, which I think is a pretty good approximation for the coastal areas of California.

| Potential Whole House Fan Energy Savings per Year for California | ||||

| Input Energy cost | $0.24 | Dollars per KWH | ||

| Application | High Speed Watts | Low Speed Watts | Energy Savings * (per Year) | |

| 2.5WHF | 288 | 250 | $777.89 | |

| 2.5eWHF | 200 | 43 | $826.70 | |

| Air Conditioning | 2808 | na | $0 | |

| * Assumptions are that the cooling season is 5 months, the WHF is run 10 hours/day, 40% use is at low speed, an average deltaT at night is 10º , and that all WHF cooling offsets AC use. | ||||

We love the validation that utilities give to the whole house fan concept by sponsoring rebates on our products. Thank You.

BUT… P.G.&E. took longer to put our new model 2.5WHF on their “qualifying list” than it took us to design, test, photograph, market, and sell the first year’s production! Wow ! We are just too quick for you utilities