Recently we have been using our new and improved sound testing chamber to make sound comparison videos of our different models. The shooting of these videos reminded us that the set up of the ducted models will make a significant difference in the CFM and noise levels. Basically, improper installation will decrease the unit CFM and increase the amount of noise. Some numbers for comparison:

Recently we have been using our new and improved sound testing chamber to make sound comparison videos of our different models. The shooting of these videos reminded us that the set up of the ducted models will make a significant difference in the CFM and noise levels. Basically, improper installation will decrease the unit CFM and increase the amount of noise. Some numbers for comparison:

AirScape 4.5 improper installation – high 59 dBA / low 50 dBA

AirScape 4.5 proper installation – high 55 dBA /low 46 dBA ……A 4 dBA difference!

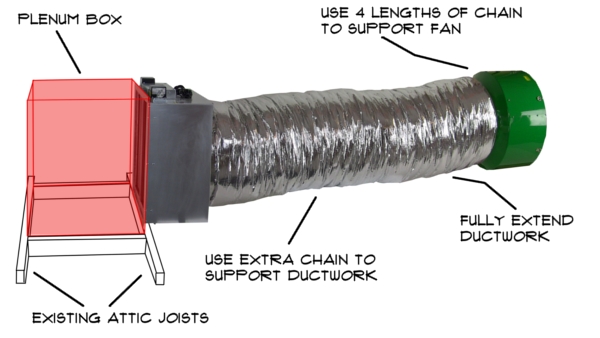

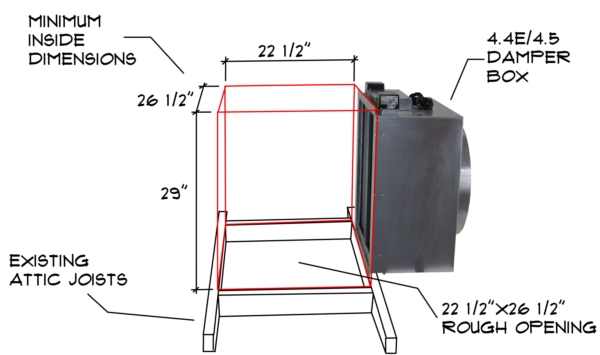

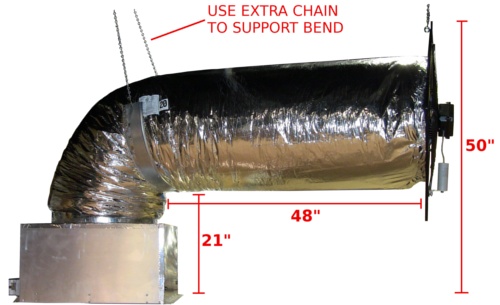

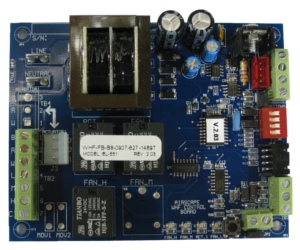

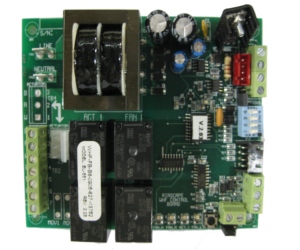

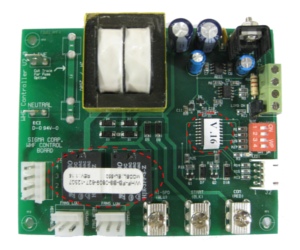

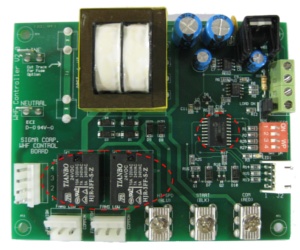

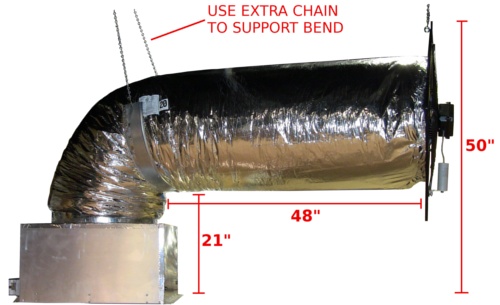

The photo above shows the correct install dimensions for the 4.5 WHF. You will notice that we have a nice even bend and the ductwork is fully extended (Note that we used an extra length of the provided chain to help support the bend). It is important to maintain the 20″ diameter of the duct through the 90 degree bend. This will ensure that you get unrestricted airflow through the duct and will help disrupt the sound waves. You also want to make sure the duct and fan are fully extended from the 90 degree bend. This moves the fan to the furthest point from the grill opening, thus decreasing the decibel level.

Airscape 2.5/2.5e installation: The install dimensions for the AirScape 2.5/2.5e are very similar. The duct should be 21″ from the attic floor. It should extend 44″ from the 90 degree bend to the fan (you may be able to extend it to 48″ if the bend is supported as shown in the photo above). The top of the fan should be 44″ from the attic floor.